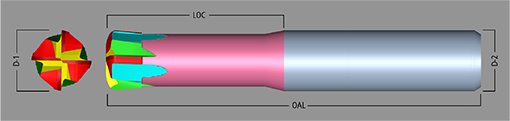

We developed our High Feed Milling End Mills to give you the ability to machine very hard materials at high

feed rates with long tool life. The cutters have a Double Corner Radius with Circular Arc on the end face that is

extremely efficient. A significant back-taper allows clearance on the periphery of the tools. These tools are outstand-

ing for face milling and slotting in Super Alloys like Inconel, pre-hardened Stainless Steel and most Tool Steels.

This type of mill is designed to excel at deep pocket milling at very high feed rates.

The High Feed cutters are available in 4 and 5 Flute geometries. Both tools allow for shallow ramping into your

material. We only sell these tools with our nano-coatings of InoxoCon for Stainless Steel and Nickel based alloys or

FerroCon for Tool steels. These coatings will allow the end mills to cut more freely and let the heat leave with the

chips while you are milling.

* F at the end means FerroCon, and I means InoxoCon Coated

| Flutes | D-1 | D-2 | OAL | LOC | Part Number |

|---|---|---|---|---|---|

| 4 | 0.2500 | 0.2500 | 2.500 | 0.100 | HFM4-250-F |

| 4 | 0.2500 | 0.2500 | 2.500 | 0.100 | HFM4-250-I |

| 4 | 0.3125 | 0.3125 | 2.500 | 0.150 | HFM4-312-F |

| 4 | 0.3125 | 0.3125 | 2.500 | 0.150 | HFM4-312-I |

| 4 | 0.3750 | 0.3750 | 2.500 | 0.175 | HFM4-375-F |

| 4 | 0.3750 | 0.3750 | 2.500 | 0.175 | HFM4-375-I |

| 4 | 0.5000 | 0.5000 | 3.000 | 0.200 | HFM4-500-F |

| 4 | 0.5000 | 0.5000 | 3.000 | 0.200 | HFM4-500-I |

| 4 | 0.6250 | 0.6250 | 3.500 | 0.250 | HFM4-625-F |

| 4 | 0.6250 | 0.6250 | 3.500 | 0.250 | HFM4-625-I |