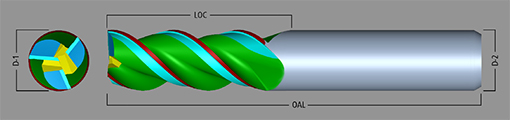

These 3 flute end mills have a geometry designed

to create a very sharp cutting edge while providing

the teeth exceptional rigidity to hold up in difficult

materials like Titanium. They have a 45° Helix

Angle, Variable Index Flutes, Eccentric Relief and

are Center Cutting, most importantly they have a

Thicker Core for added rigidity.

We offer these end mills only with InoxoCon coating for exceptional performance in materials such as Titanium and

other Nickel Based Super Alloys.

* For CHAMFERED end mills enter a C as the first character in the part number. For example a 1/2” 4 flute uncoated

end mill will have a part number or C-FT4-500. Standard Chamfer is 5% of Diameter. Any size can be requested.

* For Radius end mills enter an R as the first character in the part number. For example a 1/2” 4 flute uncoated end

mill will have a part number or R-FT4-500. Standard Radius is 5% of Diameter. Any size can be requested.

* I at the end means InoxoCon Coated

(Coolant should be used on both uncoated and ZrN coated tools)

| Flutes | D-1 | D-2 | OAL | LOC | Part Number |

|---|---|---|---|---|---|

| 3 | 0.2500 | 0.2500 | 2.500 | 0.750 | FT3T-250-I |

| 3 | 0.3125 | 0.3125 | 2.500 | 0.750 | FT3T-312-I |

| 3 | 0.3750 | 0.3750 | 2.500 | 0.875 | FT3T-375-I |

| 3 | 0.5000 | 0.5000 | 3.000 | 1.250 | FT3T-500-I |

| 3 | 0.6250 | 0.6250 | 3.500 | 1.250 | FT3T-625-I |

| 3 | 0.7500 | 0.7500 | 4.000 | 1.500 | FT3T-750-I |

| 3 | 1.0000 | 1.0000 | 4.000 | 1.500 | FT3T-1000-I |